Опис

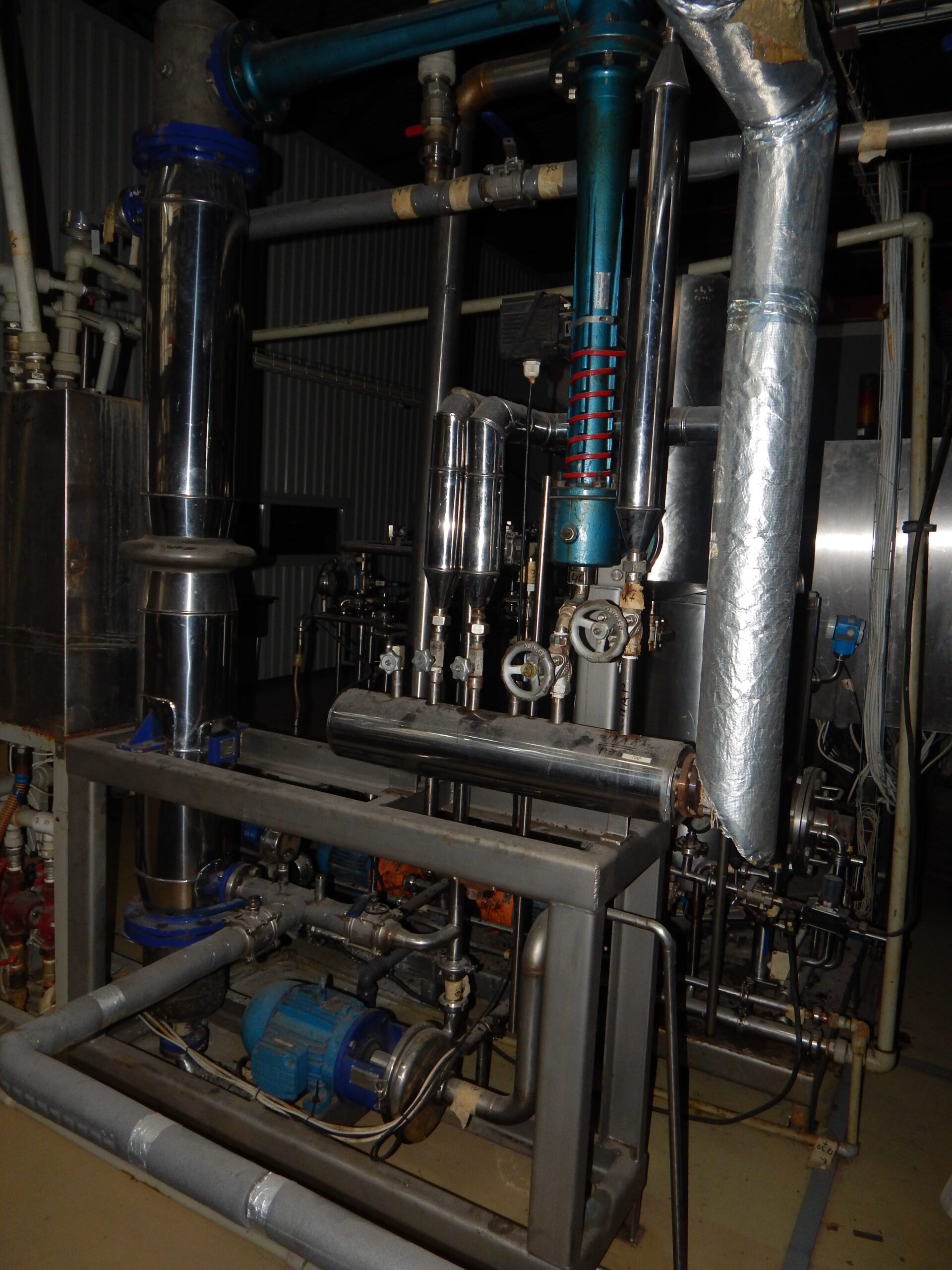

Pilot Plants

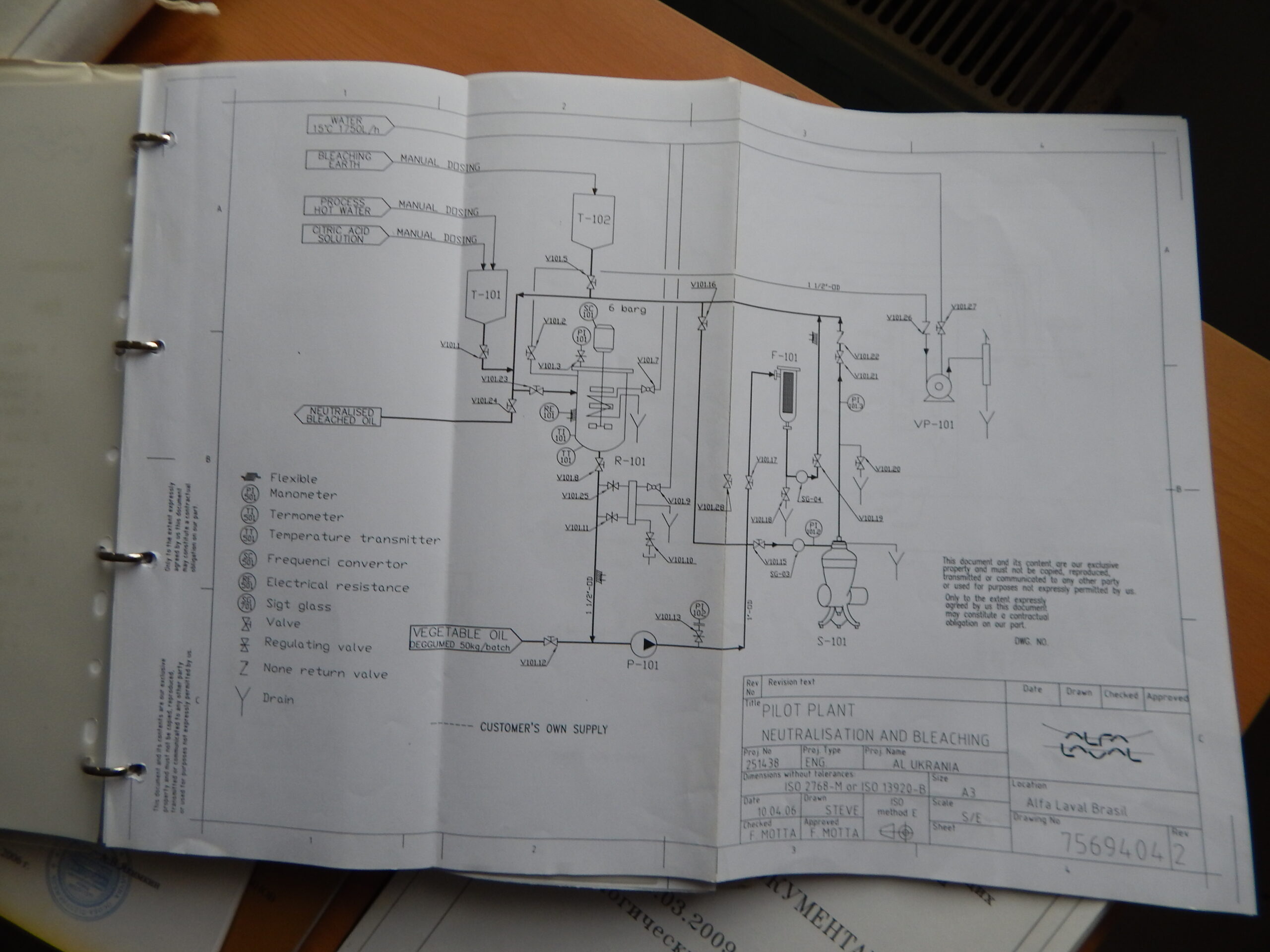

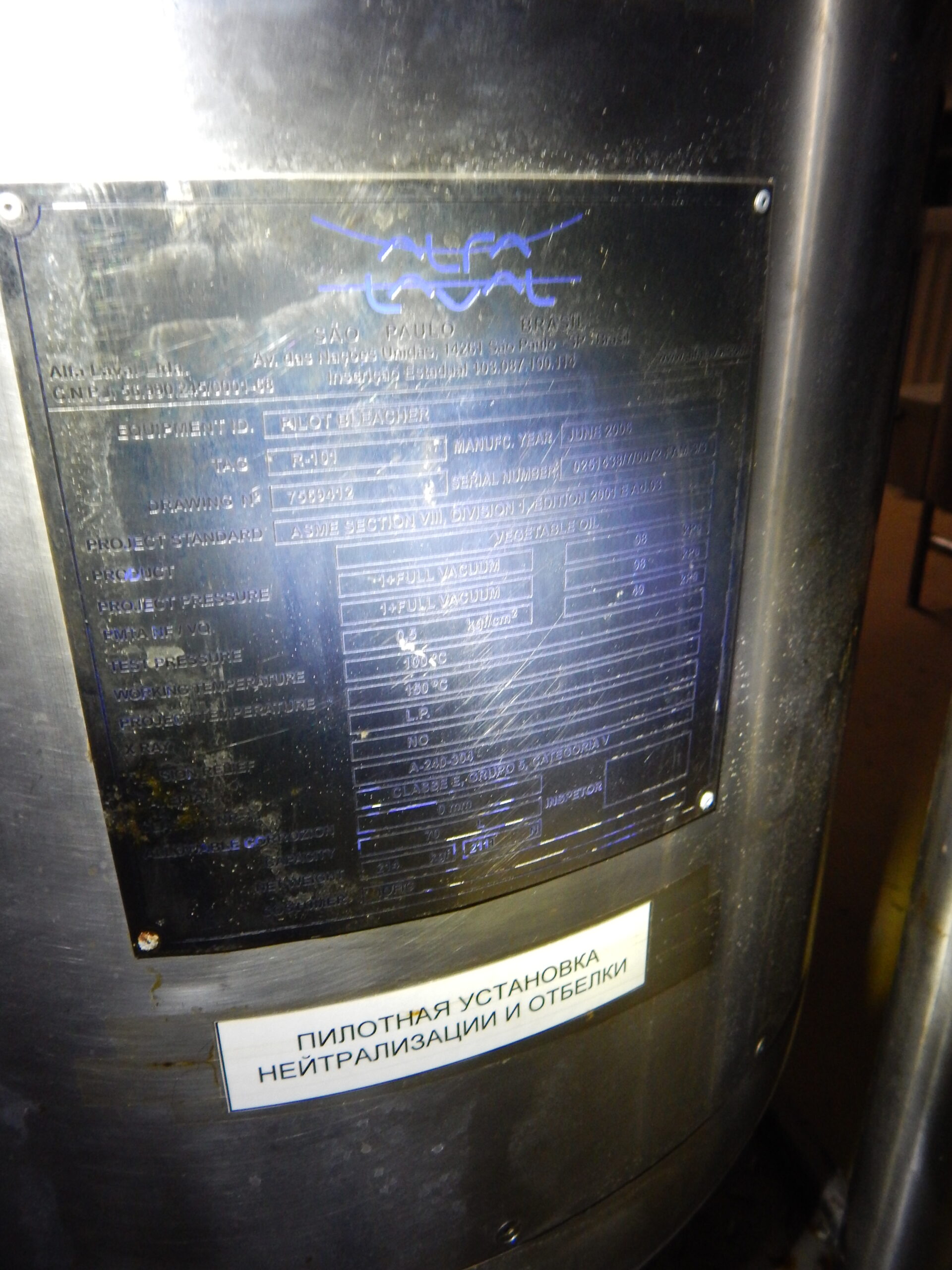

NEUTRALIZATION AND BLEACHING – 50 liters size,

The neutralization and bleaching takes place at same vessel. In a first step oil is manually added to the reactor. The oil is heated up to 80-90oC with an on-off temperature control. Phosphoric acid and lye are also manually injected.

When the reaction is completed the separation takes place through pilot separator recirculating the oil back to the reactor.

After finished the neutralization wash water is then manually added to the reactor, and recirculation through the separator takes place until the oil is completed washed.

The oil is dried in the reactor before bleaching.

Bleaching earth is added to the vessel. After the reaction time the oil is recirculated through a bag filter until it is completed clean.

ITERESTERIFICATION/HYDROGENATION- 50 liters size,

Hydrogenation, interesterification and pos-bleaching takes place at same vessel. The RB oil is added to the reactor. Temperature is adjusted up to initial reaction temperature. Catalyst is added and hydrogen is manually injected. Amount of hydrogen is manually injected and reaction is controlled by a flow indicator and time.

After analysis of the modificated oil the product is then cooled down to pos-bleaching temperature. Citric acid and bleaching earth is manually added to the reactor.

After the reaction time the product is recirculated through a bag filter until it is completed clean.

In case of interesterification the catalyst is added. During the reaction the oil is under recirculation until reaction is completed.

Phosforic acid and bleaching earth is added for the pos-treatment. The oil recirculate through the bag filter until it is completed clean.

DEODORIZATION- 50 liters size,

The oil coming from bleaching or post-treatment is then added to the pilot deodorizer. Deodorization temperature is adjusted by an electrical heater. When the deodorization time is finished and the oil analysis is ok, the product is than cooled down by water to the storage temperature.

FRACTIONATION – 50 liters size,

The oil is added to the reactor and cooled down to around 35°C with cooling water. Chilled water pass through a PHE and different temperatures can be adjusted for different time and temperature programs. After the cristalyzation finished the oil is then filter in a press filter.